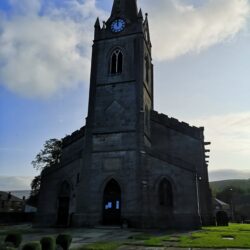

Holy Trinity in Littleborough is a Grade II Listed church, re-built around 1817. It was built because the need for a church other than St Chad’s in Rochdale was becoming more essential. The chapel was built nearer to the river than the current building and it was called Little-brucke, which eventually gave its name to the town of Littleborough. In 1660 Holy Trinity was made into a Parish Church with a congregation of 272 families, following this, the influential Halliwell family was much involved with Holy Trinity and money was made available for a schoolmaster some time around 1967, and the school was built in Ealees Lane. In 1889 a new chancel foundation stone was laid which added 57 new seats to the church. Very little has changed since 1889. A memorial cross was placed in the churchyard in honour of the fallen of World War One and the original graveyard was closed in 1940 as it was full. The stones have since been laid flat, making for easier maintenance and gives the churchyard an open aspect.

More recently the church had been suffering greatly with significant water ingress internally due to the deterioration of the current rainwater goods. This was causing issues within the church, and occasionally disrupting services. The Parochial Church Council were awarded a Covid-19 Emergency Heritage at Risk Grant which enabled the remedial works to be carried out. The church instructed Storah Architecture to schedule the works and subsequently we were awarded the contract.

The works included extensive refurbishment and replacement of cast iron rainwater goods, along with cleaning and checking of rainwater outlets to parapet gutters and additional insertion of rodding access to allow for easier future cleaning and maintenance. In order to carry out the works, access was gained using an Aluminium tower by PASMA-trained operatives rather than traditional scaffolding methods in order to not cause any impact on the historic fabric of the building. Materials were sourced from Hargreaves Foundry, Halifax, as per the architects specification. Rainwater goods were traditional cast iron, pre-painted, 75mm & 100mm diameter eared downpipes, cast iron eared anti-splash shoes, cast iron offsets and cast iron hoppers. During the project, the church remained opened for ceremonies such as funerals, where we had to retract from site during these times. The works were planned as to not cause disruption to the scheduled programme as the project completion date had to coincide with the Easter celebrations. Task specific PPE was used on this project along with additional fall protection due to working at height. Safety & Environmental concerns included weather monitoring along with exclusion zones in place whilst using the access tower. Weekly progress meetings covering any changes or discoveries were held, such as encountering bird nests, followed by a final snagging meeting prior to handover and completion.